| Date | February 2014 to December 2014 |

| Location | Lahore, Pakistan |

| Organization | Sui Northern Gas Pipelines Limited (SNGPL) |

| Position | Executive Engineer Metering |

[CE 3.1]

Sui Northern Gas Pipeline Limited (SNGPL) is the largest integrated company serving more than 5.3 million consumers by covering 250 mains town in North central Pakistan and is certified against ISO 14001:2004 & OHSAS 18001:2007 Standards. SNGPL’s 11 sites have been registered under the "SMART2" Program by Pakistan Environmental Protection Agency (PAK-EPA). The company has 50 years of experience in operation and maintenance of high pressure gas transmission and distribution system. Sui Northern Gas Pipeline Limited operates with 10,000 employees in a region of nation that has rapidly growing demands for Natural Gas. In accordance with growth in Oil and Gas industry of Pakistan. It has also expanded its activities as Engineering, Procurement and Construction (EPC) Contractor to undertake the planning, designing and construction of pipelines, both for itself and other organizations.

[CE 3.2]

Metering department is focused on designing, developing innovative and technologically advanced natural gas meters for domestic, commercial and industry. Our metering assortment includes a comprehensive range of premium quality metering gadgets, advanced infrastructure and energy management systems. We are proud of our customer associations and our firm approach ensures that we deliver to Sui Northern Gas Pipeline customers’ requirements and exceed expectations. Metering Department is accountable for inspection, repair, maintenance, calibration, flow proving and configuration of domestic, commercial and industrial meters by employing advanced measuring and calibration equipment. We have also established in-house repairing and calibration facilities at Lahore, Faisalabad, Islamabad and Multan.We utilize Electronic Volume Correctors (EVCs) for accurate registration of Natural gas consumed on hourly, daily and monthly basis and modems (GSM/GPRS) to communicate that aforementioned data to our central server for as and when required basis to the management and concerned for inspection. We recognize that timely and accurate data is imperative to good resource management. It’s how you stay receptive to your valued customers. And how, together, we can make perennial connections that improve the quality of life for communities across Pakistan. We are ISO certified and committed to maintain the highest standards of quality keeping in line with ISO 9001:2015. We design our systems to comply with the relevant international metering standards, for example ANSI, OIML.

[CE 3.3]

The objective was to augment the design of Industrial Elster RVG Gas Meters and I- Meters to mitigate the intermittent flow characteristics and to made it temper proof. So that it could not be tempered by consumer in order to secure Unregistered Gas. That intermittent behavior of Gas Meters was the root cause of Unaccounted Natural Gas and the company was unable to utilize its assets efficiently.

[CE 3.4]

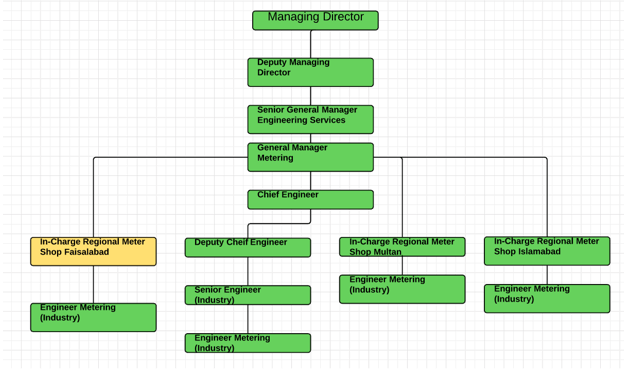

My Company hierarchy is shown in the following diagram. My position is highlighted in yellow.

[CE 3.5]

My responsibilities were as following but not limited to

I was responsible to analyze the process variables received from Electronic Volume Corrector installed against each industrial consumer and to generate meter inspection report to bill the respective consumer. I developed the data managements system where the company executives can easily access and calculate the volume of Natural Gas consumed. It also showed the graphical relationship between different variables e.g. Pressure Vs Consumption, Flow profile etc. It was appreciated by General Manager Metering.

I prepared the time schedule against revamping of existing infrastructure for repairing of domestic and industrial meters. I followed the plan and finished the project 2months earlier against its deadline. Previously we were able to handle only 25,000 meters, which was increased to 50,000. I proposed various modifications during this expansion and successfully installed the Sonic Flow Provera which had the capacity of 10 Meters to flow prove at the same time. Informed the senior management about the ongoing expansion project and got approvals of necessary resources proactively.

Being the head of Faisalabad region I successfully completed the installation of GPRS system on the premises of Industrial consumers which enabled us to monitor the natural gas consumption pattern of respective consumer on hourly, daily and monthly basis. We had 600 Nos of industrial consumers where we installed meters with Electronic Volume Corrector and GPRS modem for data transmission to head office Lahore so that management could be in position to gauge the performance of different regions. I logged all the ongoing activities by keeping top management in loop and made necessary modifications during the execution stage.

I devised the procedure to carry out tool box talk on workshop floor, mass safety talks, jobsite safety reviews and regular training of health and safety at workplace in accordance to OSHAS standards. I prepared the data of all working staff employed at high noise area. This helped me to rotate the job on regular basis to avoid the hearing loss of staff. That initiative promoted the safety culture by reducing the down time by making 90% compliance of safety standards at workplace. That initiative was appraised by the senior management.

I installed the fire hydrant and smoke detection system to newly built Regional Meter Shop building and connected these systems to already available infrastructure. It was designed by third party contractor. I tested all the instruments attached and verified the system integrity by the evaluation according to international standards of NFPA-24 (National Fire Protection Association). I also prepared weekly reports for senior management to update them about ongoing installation and testing project.

[CE 3.6]

I did a lot of problem solving activities.

Some of the most prominent were -

I am working as a Manager of Metering Shop where we are engaged in repairing of domestic, commercial, Industrial gas meters. We are dealing with two significant regions of the company with 1 Million consumers. After joining Metering department as a manager I initiated a plan to ameliorate the repairing rate of Gas Meters with improved accuracy which was a challenge. Therefore, I prepared a plan of action to solve these issues as well as creating the homogeneity among the different departments through leading and facilitating them. This enabled me to gauge the bottlenecks at various sections of the schematic flow and their necessary corrective measures. Gas Meter repairing process involves different sections including, Meter Receiving, Repairing, Leak, Flow Proving, Paint and Dispatch sections. In order to improve targets there were different type of handicaps with different sections. One of the major obstacle with Flow Proving section was the adaptability of new installed Sonic Prover and higher rejection rate due to leakage of meters. Meter mechanics did not want to increase their daily repairing progress to desired level of 10 Meters per day. Whereas Paint section had also the procedural and behavioral issues. However, I was committed to accomplish the defined targets, increase the productivity level and reduce the defect rates.

First, I prepared a plan of action to solve these issues as well as creating the homogeneity among the different section through leading and facilitating them. Which enabled me to gauge the bottlenecks at various sections of the schematic flow and their necessary corrective measures. I analyzed the historic data of different sections to fragment the workers according to theirskills and knowledge. I arranged a meeting with employees of different sections and informed them about the challenging situation. I had formed a team comprised of four persons with representation of each section and delegated the power to line supervisors for rapidimplementation of changes devised.

Secondly, I had started a training program to uplift the skills of mechanics. I designed experiments to study the effect of modifications in procedures on the progress and the optimum resourcesrequired at each stage. This analysis enabled me to divert excessive resources to the sectionsequipped with least ones. I envisaged that by increasing leak test pressure, our goal of increasing the progress of flow proving section could be realized. Therefore, I suggested to increase leak test pressure from 1 psig to 7 pound per square inch Psig and handled systematic soldiering of the workers’ union representatives by job rotation. That augmentation had a great impact in realization of goals.

Finally, by employing scientific management principles we were able to reduce the defects per million opportunities and increased the level of co-ordination among the different sections, makingthem understand each other’s work for smooth operation. Presently we have only two numbers of defects in the sample of 1000 meters and daily progress of meter mechanic was increased to 10meters per day. Efficiency of flow proving section was also increased by 32%, and numbers ofrepaired meters escalated from 30,000 to 40,000 with 0.1% defects which reduced 15% measurement error by condensing 2% unaccounted gas volume.

Electronic volume correctors installed on industrial meters were used to log the data on hourly basis against the consumption of Natural Gas. We were facing display off problem on frequently basis, because EVC was operated by Alkaline Battery of 4.5 Volts. These volts were produced by the installation of three cells with magnitude of 1.5 Volts in series. Battery drainage was the major reason of display off which halted the registration of data and we were unable to measure the exact amount of Natural Gas consumed by the consumer. I studied the whole problem and logged the total drainage time of alkaline battery where I observed that whole circuit was designed to operate on 3.6 Volts. There was an additional circuit installed whose objective was to filter the excessive volts. I searched for other options to eliminate that issue. After my analysis and studying the manuals, I concluded that there were two other options by which we can solve the prevailing problem. First was the replacement of alkaline battery with Lithium Ion battery of 3.6 Volts. I replaced and found the improved battery life as compared with alkaline battery. Whereas second option was to connect the existing solar panel to that alkaline battery in order to charge accordingly. It was highly appreciated by senior management, because this solution enabled us to cater root cause of display off problem.

[CE 3.7]

I used different software to gauge the efficiency of modification. I installed different type of EVCs to record the data. Firstly, I installed the modified meter against the Roots meter (Manufactured by General Electric - oil & Gas) which had excellent flow measuring profile as compared to RVG-250 Gas meters. After downloading the data I calculated the total load of both meters. I measured different profiles of Zero pressure vs Flow, Zero minimum pressure Vs Temperature, Corrected Flow Vs Pressure, Uncorrected Flow Vs Temperature. By analyzing and comparing all the data I concluded that the modification was in accordance to design of ANSI B-109.3 standards. I also ensured the tempering resistance and checked the integrity.

[CE 3.8]

I followed ANSI B 109.1, 109.2, 109.3 and OIML (International Organization of Legal Metrology) standards.

[CE 3.9]

During installation of meter, I had arranged special training to personnel involved about safe handling procedure. And, subordinate staff were advised to equip themselves with provided safety gears.

[CE 3.10]

I have worked with nine subordinate staff and we had meeting twice a week to update the General Manager Metering.

[CE 3.11]

I had to select the best supplier to make the order of worm wheel gears. I asked to supply the sample for testing form three well known suppliers and after testing in accordance to ANSI B109 Standard approved one and order to supply the material. I presented two different scenarios for using different roots of pipeline and calculated the distance. Finally, the seniors considered the option with least distance i.e. 1098 Km and the rest was 1128 Km.

[CE 3.12]

In our company we were not using Gauss/Tesla meters to gauge the strength of magnetic coupling of industrial meters during the repairing process. I presented the case and got approval to procure the F.B BELL tesla 5170 meters with range of 3 to 30 Kilo Gauss to ensure the strength of magnetic coupling. This development was accepted and appreciated.

The executed project empowered me to accomplish the challenges, especially project management, testing & evaluation phase experience & enabled me to cooperative effectively with different allied department like distribution & billing.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)