| Date | June 2012 to November 2012 |

| Location | Lahore, Pakistan |

| Organization | Sui Northern Gas Pipelines Limited (SNGPL) |

| Position | Engineer LNG-LPG Grade III |

[CE 2.1]

Sui Northern Gas Pipeline Limited (SNGPL) is the largest integrated company serving more than 5.3 million consumers by covering 250 mains town in North central Pakistan and is certified against ISO 14001:2004 & OHSAS 18001:2007 Standards. SNGPL’s 11 sites have been registered under the "SMART2" Program by Pakistan Environmental Protection Agency (PAK-EPA). The company has 50 years of experience in operation and maintenance of high pressure gas transmission and distribution system. Sui Northern Gas Pipeline Limited operates with 10,000 employees in a region of nation that has rapidly growing demands for Natural Gas. In accordance with growth in Oil and Gas industry of Pakistan. It has also expanded its activities as Engineering, Procurement and Construction (EPC) Contractor to undertake the planning, designing and construction of pipelines, both for itself and other organizations.

[CE 2.2]

The LNG-LPG department is established to make necessary arrangements to equate the supply and demand requirements. Pakistan is facing a n acute shortage of natural gas, therefore Government of Pakistan directed the Gas utility companies operating in the country to work on alternate means to address the gas shortage. LPG-LNG department undertakes project on LPG & LNG & also deals with supply of LPG-Air mix to specific industrial/domestic areas through distribution pipeline networks & or standalone basis to cater to shortfall of gas. It also deals with LNG projects to cater a long term gas shortage issue & LPG pipeline project to cater country energy requirements.

[CE 2.3]

The overall project was to develop simulation study by using Hysis for LPG transportation through pipeline from Karachi Port Qasim to Sheikhupura (Punjab) by drawing 1000 ton per day at Multan, 1500 Ton per day at Faisalabad and 2500 Tons per day at Sheikhupura. The locations of existing refineries and LPG plants in the country which are major source of LPG have also been taken into account while short listing the route corridors. The total length of pipeline was 1098Kms

[CE 2.4]

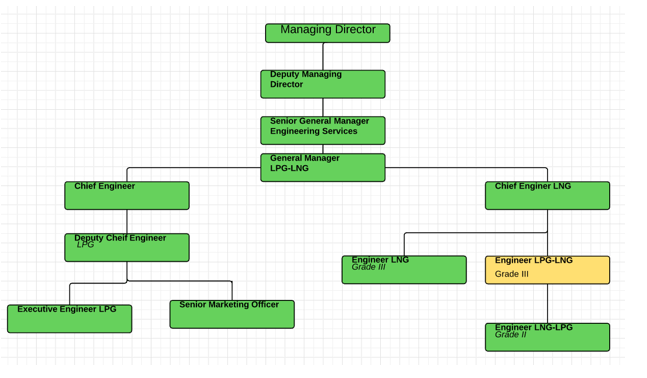

My Company hierarchy is shown in the following diagram. My position is highlighted in yellow.

[CE 2.5]

My responsibilities were as following but not limited to -

I successfully implemented the LPG Auto Gas business plan under the head of SNGPL Franchise scheme. I was responsible to ensure the compliance of Regulatory body’s defined(OGRA) standard of lay out plan, equipment installation and legal requirement. Under this scheme I accomplished the targets first in Lahore and then to other cities of Punjab.

I prepared time schedule to carry out Energy Audits of different industrial consumers under the Government Scheme of Energy conversation. I discovered the boilers installed at various commercial units for captive power production were operating below their rated heat efficiency. All the consumers with low efficiency were advised to upgrade their existing system or to add waste heat recovery units in order to increase the heat efficiency.

I was assigned to prepare a feasibility study for revamping of two Liquefied Petroleum Gas bottling plants installed near Lahore and Kohat area which were used to transfer LPG from storage facility to cylinders of different capacities. I prepared a report for senior management explaining all the different scenarios which were self-explanatory. I discussed the complete requirement of new machines and also the up gradation of some existing gears.

I successfully carried out the Job Hazard Analysis of different section at LPG bottling and synthetic Natural Gas facilities. The synthetic Gas was the mixture of LPG and Air with varied composition to meet the Wobbe Index. I fragmented the whole process schematic flow in different sections comprising of Pumping area, LPG Heater, Storage Area, LPG-Air Mixer, Gas Chromatograph, measuring units with AGA standards and defined the potential hazards associated with each unit.

I was responsible to prepare tender documents of various LNG and LPG projects. I formulated different tenders comprising of LPG + Air mix with capacity of 05, 10 MMSCFD (Million Standard Cubic Feet per Day) capacities and successfully evaluated the coming bids in accordance to PEPRA (Public Procurement Regularity Authority) rules. I also prepared a tender document for solar water heater scheme. Its purpose was to augment it with gas heater for domestic gas consumers. I answered the quarries of different bidders promptly which was dully appraised by senior management. I presented the summary of ongoing tenders and their progress to senior management weekly.

[CE 2.6]

I did a lot of problem solving activities. Some of the most prominent were

Our Department was assigned a project to prepare a feasibility report to mix the Biro Gas produced and the Natural gas to expand the distribution network. The team of five members worked very hard to prepare the report but it got stuck at the convergence of Column which was used to remove impurities from bio gas before the mixing of both gases. The task was assigned to me to carry out simulation work. I requested to provide all the relevant data before I could start the work. After a thoughtful process I succeeded in converging the contactor column and acquired the desirable range of impurities in stream coming out from the column.

During winter season, we had a severe shortage of Natural Gas in our distribution networks; therefore company decided to install Synthetic Gas (LPG+ Air) plant at different localities. Firstly, we have to install the system on domestic consumers only, for that purpose the selection of LPG + Air mix site was a crucial activity. I played a vital role in order to locate the cluster of domestic consumer and assisted the management to a well-informed and rational decision. I scrutinized the existing networks of far-flung areas, which could easily be connected to Synthetic Gas network. I suggested two locations, one near Faisalabad city and the other near Gujranwala city.

[CE 2.7]

I had performed calculations by using Aspen HYSYS; all the options of LPG pipeline system are modeled along with the simulation of LPG storage requirements and calculation of horsepower of intermediate pumping stations. The pressure drop due to friction in a pipeline depends on the flow rate, pipe diameter, pipe roughness, liquid specific gravity, and viscosity. In addition, the frictional pressure drop depends on the Reynolds number (and hence the flow regime). For this study the pressure drop due to friction in pipeline, expressed in feet of liquid head (h), is calculated by using the Darcy-Weisbach equation. Similarly, for the calculation of friction/transmission factor, Colebrook White equation is used in Aspen HYSYS. The operating pressure was 250 Psig and this is the function of pipe diameter, length, pipeline elevation profile, liquid viscosity and flow rate.

[CE 2.8]

I followed ASME B 31.4, NFPA 59, ANSI B16.5 – 1988, API 5L

[CE 2.9]

I selected that route of pipeline In order to avoid the areas such as National Parks, Special Military protection areas and special areas of conservation. I also considered the route where least densely populated areas were present.

[CE 2.10]

A team of five subordinate staff were deputed to assist me. We had meeting on daily basis to plan and forecast the stated objectives. I attend meetings with my senior on weekly basis to update regarding the progress.

[CE 2.11]

A third part contractor was engaged for the Revamping of LPG Bottling plant. I coordinated and assisted him regarding the completion of job.

[CE 2.12]

I presented two different scenarios for using different roots of pipeline and calculated the distance. Finally, the seniors considered the option with least distance i.e. 1098 Km and the rest was 1128 Km.

[CE 2.13]

I started “In House Training and Routine Safety Audit “system for dissemination of job related knowledge. I also presented a suggestion to senior management that all Executive should be advised to take part in that initiative which was also appraised by management. By implementing this system our job related incidents had been drastically reduced and in office agronomic conditions was improved.

During this Project I developed the skills of conflict management, co-ordination among different stake holders, time & project management. I performed hectic work on Hysis & developed skills of learning from Internet.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)