| Time duration | September 2016 to December 2016 |

| Location | Malaysia |

| Organization | International Islamic University Malaysia |

| Project | Structural Analysis & Design Office |

| Position |

[CE 2.1]

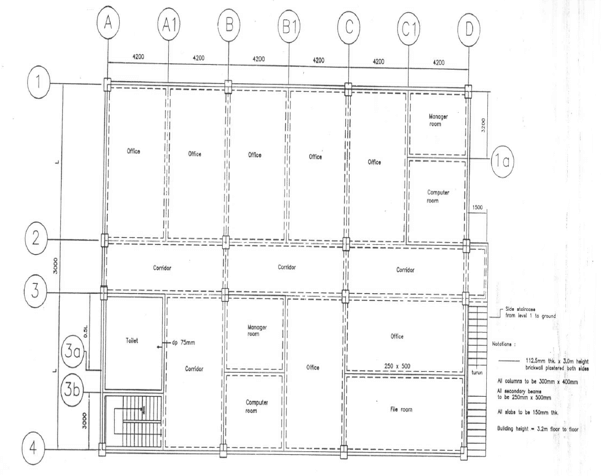

This career episode relates to project titled “Structural Analysis & Design Office’’. The project was assigned to me as a part of my 4th Year 1st Semester of engineering at International Islamic University Malaysia.

[CE 2.2]

I was required to prepare design report on the following beam, slab and staircases.

[CE 2.4]

The project Hierarchy is given below -

[CE 2.5]

| Office | Ceramic tiles on in-situ reinforced solid slab. Suspended ceiling bellows beams. Lightweight partitions as required to offices. |

| Manager room | Carpets on in-situ reinforced concrete solid slab. Suspended ceiling below beams |

| Corridor | Ceramic tiles on in-situ reinforced concrete solid slab. Suspended ceiling below beams |

| Files room | Cement render on in-situ reinforced concrete slab. No ceiling under. |

| Computer rooms | Carpets on in-situ reinforced concrete solid slab. Suspended ceiling below beams |

| Staircase | Ceramic tiles on in-situ reinforced concrete. Enclosed in 112.5mm x 3.0m height brickwork plastered on both sides. |

| Toilet | Ceramic tiles on in-situ reinforced concrete slab. No ceiling under. All internal walling lightweight partition. Enclosed in 112.5mm x 3.0m height brickwork plastered on both sides. |

| External wall | generally 112.5mm x 3.0m height brickwork plastered on both side. |

| Fire protection | All elements of the construction to have minimum of 1 hour fire resistance. |

[CE 2.6]

I did following calculations

Concrete Unit weight = 25 kN/m2

Brickwall unit weight = 2.6 kN/m2

Brickwall height = 3 m

Concrete render = 0.3 kN/m2

Ceramic tiles = 1 kN/m2

Lightweight partitions = 1 kN/m2

Building Services = 0.3 kN/m2

Ceiling = 0.5 kN/m2

Carpet = 0.05 kN/m2

Primary beam = 250 x 650 mm

Secondary beam = 250 x 500 mm

Slab thickness = 150 mm

Assumed Bars:

Ø bar 1 = 20 mm

Ø bar 2 = 16 mm

Ø link = 6 mm

Imposed Load, Qk

Office = 2.5 kN/m2

Corridor = 3.0 kN.m2

File Room = 5.0 kN/m2

Manager Room = 2.5 kN/m2M

Computer Room = 3.5 kN/m2

Dead Load & Imposed Load for each room:

Office:

Dead Load:

Slab self-weight = 25(0.15) = 3.75 kN/m2

Cement render = 0.30 kN/m2

Ceramic Tiles = 1.0 kN/m2

Lightweight partitions = 1.0 kN/m2

Building Services = 0.3 kN/m2

Ceiling = 0.5 kN/m2

Gk = 6.85 kN/m2

Imposed Load,

Qk = 2.5 kN/m2

[CE 2.7]

I also did calculations for Durability, Fire and Bond requirements

Min, cover with regard to bond cmin, b = 20 mm

Min, cover with regard to durability cmin, dur = 20 mm

Min required axis distance for R60 fire resistance,

asd = 30+10 = 40 mm

Min cover with regard to fire = Cmin = asd - ꬾlink -ꬾbar/2

= 40-6-20/2 = 24mmAllowance in design for deviation, ∆Cdev = 10mm

Nominal cover, Cnom = Cmin + ∆Cdev = 24+10 = 34mm

[CE 2.8]

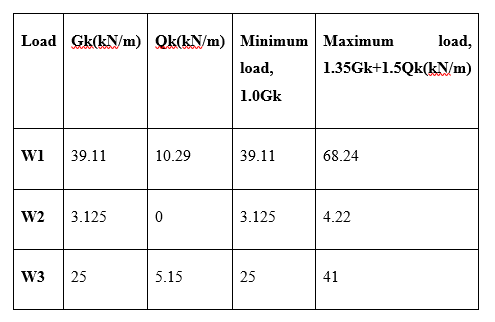

Beam C/1-2

Ly/Lx = 5800/4200 = 1.38<2 (two-way slab)

Shear Coefficient βv =0.49

Slab Gk = 6.85 kN/m2 (office)

Slab Qk = 2.5 kN/m2 (office)

Beam self-weight = 25(0.65-0.15)x0.25=3.125 kN/m2

Brick weight = 2.6 x 3 = 7.8 kN/m2

Dead load from slab B1-C1/1-2: 2x(0.49)4.2x6.85 = 28.19 kN/m2

Gk = 28.19 + 3.125 + 7.8 = 39.11 kN/m

Imposed load from slab B1-C1/1-2

= 2x(0.49)4.2(2.5)=10.29kN/m2

Qk = 10.29 kN/m

Total Design load (W1)

W1 = 1.35 Gk + 1.5Qk

W1 = 1.35(39.11) +1.5(10.29) = 68.24 kN/m

Corridor

Slab Gk = 5.85 kN/m2

Slab Qk = 3 kN/m2

Load on beam C/2-3

Beam self-weight = 25(0.65-0.15) x 0.25=3.125 kN/m

Gk 3.125 = 3.125 kN/m2

Qk = 0 kN/m2

(Qk=0 because it is one-way and has no effects on beam C/2-3)

W2 = 1.35 (3.125) + 1.5(0)= 4.22 kN/m

I ignored the slab weight because it has no effects on the beam.

[CE 2.9]

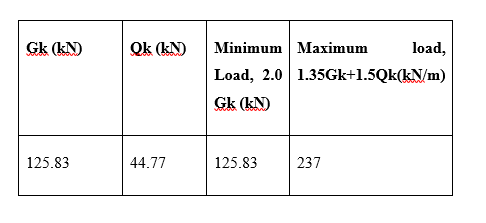

I did Uniform load setup as following

Uniform load (W)

Point load (P)

[CE 2.10]

I did effective flange width as following

beff = ∑beff I + bw < b

beff I = 0.2bi + 0.1l0 < 0.2l0

Span C/1-2

bw = 250mm

hf = 150mm

h = 650mm

b1 = 1975 mm

b2 = 1975 mm

Actual flange width, b = b1 + b2 + bw = 1975+1975+250 = 4200mm

beff = ∑beff I + bw < b

beff I = 0.2bi + 0.1l0 < 0.2l0

l0 = 0.85l = 0.85 x 5800 = 4930 mm

beff 1 = 888 mm < 986 mm Use: 888 mm

beff 2 = 888 mm < 986 mm Use: 888mm

beff = 888 + 888 + 250 = 2026 mm < 4200mm

Span C/2-3

l0 = 0.7l = 0.7 x 3000 = 2100 mm

b1 = 1975 mm

b2 = 1975 mm

beff 1 = 605 mm > 420 mm Use: 420 mm

beff 2 = 605 mm > 420 mm Use: 420 mm

beff = 420 + 420 + 250 = 1090 mm < 4200mm

Span C/3-4

bw = 250mm

hf = 150mm

h = 650mm

b1 = 1975 mm

b2 = 4075 mm

Actual flange width, b = b1 + b2 + bw = 1975+4075+250 = 6300 mm

beff = ∑beff I + bw < b

beff I = 0.2bi + 0.1l0 < 0.2l0

l0 = 0.85l = 0.85 x 5800 = 4930 mm

beff 1 = 888 mm < 986 mm Use: 888 mm

beff 2 = 1308 mm > 986 mm Use: 986 mm

beff = 888 + 986 + 250 = 2124 mm < 6300 mm

[CE 2.11]

Main reinforcement was calculated as below

Span C/1-2

Effective depth (d) = h-Cnom - Ø link -1.5 Ø bar = 650-35-6-1.5x20 = 579 mm

Bending moment,

M = 216 KN.m

Mf = 0.565 Fck b hf (d-0.5hf) = 0.565 x 25 x 2026 x 150 x (579-0.5x150) = 2163.5 KN.m

M < Mf (Neutral axis is in the flange)

K = M /fckbd2 = 216x106 / (25x2026x5792) = 0.013

Z = d[0.5 + √(2& 0.25-k/(1.134 ) )] = 579 [0.5 + √(2& 0.25-0.013/(1.134 ) )] = 572.8 mm

As = M / 0.87Fyk Z = 216x106 /0.87x500 x 572.8

= 866 mm2

Minimum and Maximum reinforcement area:

As,min = 0.0013bd

0.0013bd = 0.0013x250x579 = 188.17 mm2

As,max = 0.04bh = 0.04x250x650 = 6500 mm2

[CE 2.12]

Slab Design

Assumptions

Ø bar = 10 mm

Concrete Unit weight = 25 kN/m2

Concrete render = 0.3 kN/m2

Materials:

Unit weight of concrete = 25 KN/m3

Characteristic strength of concrete, Fck = 25 KN/m2

Characteristic strength of steel, Fyk = 500 KN/m2

Primary beam = 250 x 650 mm

Secondary beam = 250 x 500 mm

Slab thickness = 150 mm

Slab thickness = 150 mm

Durability, Fire and Bond requirements

Min, cover with regard to bond cmin, b = 10 mm

Min, cover with regard to durability cmin, dur = 15 mm

Min required axis distance for R60 fire resistance,

a = 20 mm

Min cover with regard to fire = Cmin = a -0.5 Ø bar = 20-10/2 = 15 mm

Allowance in design for deviation, ∆Cdev = 10mm

Nominal cover, Cnom = Cmin + ∆Cdev = 15+10 = 25 mm

[CE 2.13]

I did shear force calculations as following

Two-way restrained slab

B1-C/1-2, C-C1/1-2, B1-C/3-4 (Office)

Long span Ly = 5800 mm

Short span Lx = 4200 mm

y / Lx = 1.4 < 2.0 (Two-way slab)

Case 2: One short edge discontinuous

Short Span:

Vsx1 = βsx1 nd Lx = (0.45) (13) (4.2) = 24.57 KN

Vsx2 = βsx2 nd Lx = (0.45) (13) (4.2) = 24.57 KN

Long Span:

Vsy1 = βsy1 nd Lx = (0.36) (13) (4.2)= 19.66 KN

Vsy2 = βsy2 nd Lx = (0.24) (13) (4.2) = 13.10KN

Design force VEd = 24.57 KN

Design shear resistance,

VRd,c = [0.12k(100 ρ 1Fck )1/3]bd

K = 1+ (200/d)1/2 < 2.0

K = 1+ (200/120)1/2 < 2.0

2.29>2.0 use 2.0

ρ 1 = As1/bd < 0.02

ρ 1 = 314/1000x120 < 0.02 = 0.003<0.02

VRd,c = [0.12x2(100 x0.003x25 )1/3]1000x120

= 56374 N = 56.4 KN

Vmin = [ 0.035K3/2 Fck1/2] bd

= 0.035 x 23/2 x 250.5 x 1000 x 120 = 59.4 KN

So, VRd,c = 56.4 KN > VEd

[CE 2.14]

I completed the project report efficiently and within the stipulated time. I did all the management of the project and calculated multiple aspects of the project very well. In case of any issues I always contacted my project supervisor. I also consulted internet resources and library for resolving the calculation issues.