| Time duration | 2015 to 2016 |

| Location | Malaysia |

| Organization | International Islamic University Malaysia |

| Project | Ready Mix Concrete (RMC) |

| Position |

[CE 1.1]

This career episode relates to project titled “Ready Mix Concrete Mix (RMC)’’. The project was assigned to me as a part of my 3rd Year 1st Semester of engineering at International Islamic University Malaysia.

[CE 1.2]

Ready mix concrete was first patented in Germany in 1903, its commercial delivery was not possible due to lack of transportation needs. The first commercial delivery was made in Baltimore USA in 1913.The first revolving drum type transit mixer was developed in 1926.

The National Ready-Mixed Concrete Association of Malaysia (NRMCA) was established in 1987 and has been recognized as the national association for the suppliers of ready-mixed concrete in the Peninsular Malaysia. Members of NRMCA are mainly the major players in the industry and our 26 members supply about 70% of the total consumption of concrete.

[CE 1.3]

Few things are more aggravating to produce on a worksite than concrete. Bags of cement, sand, aggregate (gravel) and possibly other additives must be delivered to the construction area. A supply of clean water is also necessary, along with a rented concrete mixing hopper. Even after all the dusty and heavy ingredients have been loaded into the hopper, one small error in the wet/dry ratio can render an entire batch of concrete unusable. One common solution to this messy and time-consuming problem is “READY MIX CONCRETE”

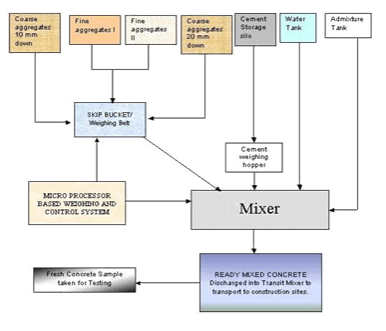

Ready-mix concrete (RMC) is a ready-to-use material, with predetermined mixture of cement, sand, aggregates and water. RMC is a type of concrete manufactured in a factory according to a set recipe or as per specifications of the customer, at a centrally located batching plant.

It is delivered to a worksite, often in truck mixers capable of mixing the ingredients of the concrete en-route or just before delivery of the batch. This results in a precise mixture, allowing specialty concrete mixtures to be developed and implemented on construction sites. The second option available is to mix the concrete at the batching plant and deliver the mixed concrete to the site in an agitator truck, which keeps the mixed concrete in correct form.

For growth of the industry, government bodies, private builders, architects/engineers, contractors, and individuals required to be made fully aware about the advantages of using ready mix concrete, government bodies/consultants need to include ready mix concrete as mandatory in their specification for execution, government specifications for CPWD and PWD jobs should include Ready mix concrete as a mandatory item. Apart from this tax breaks are required for the growth of RMC and developers/contractors needs to be discouraged from piling up materials like metal, sand etc. on roads/foot paths.

[CE 1.4]

The project Hierarchy is given below -

[CE 1.5]

For construction most of the contractors and builders must collect the raw materials required for the construction before starting actual works. These materials should be stored at the site properly. This technique can be possible when there will be more empty space at the construction site which is not possible in congested areas. At this time there is one solution to overcome all these problems that is nothing “READY MIX CONCRETE”.

By using R.M.C we can save the time and money required for the labors. I drafted following places where ready mix concrete can be used -

[CE 1.6]

Admixture: A substance added to the basic concrete mixture to alter one or more properties of the concrete; i.e. fibrous materials for reinforcing, water repellent treatments, and coloring compounds.

Aggregate: Inert particles (i.e. gravel, sand, and stone) added to cement and water to form concrete.

Cement: Dry powder that reacts chemically with water to bind the particles of aggregate, forming concrete. Portland cement is typically used in concrete production.

Fly ash: Fly ash is a by-product from coal-fired electricity generating power plants. The coal used in these power plants is mainly composed of combustible elements such as carbon, hydrogen and oxygen (nitrogen and sulfur being minor elements), and non-combustible impurities (10 to 40%) usually present in the form of clay, shale, quartz, feldspar and limestone. As the coal travels through the high-temperature zone in the furnace, the combustible elements of the coal are burnt off, whereas the mineral impurities of the coal fuse and chemically recombine to produce various crystalline phases of the molten ash. The molten ash is entrained in the flue gas and cools rapidly, when leaving the combustion zone (e.g. from 1500°C to 200°C in few seconds), into spherical, glassy particles. Most of these particles fly out with the flue gas stream and are therefore called fly ash. The fly ash is then collected in electrostatic precipitators or bag houses and the fineness of the fly ash can be controlled by how and where the particles are collected.

[CE 1.7]

Equuipement Required for RMC

Batching

Storage is done by following methods

Inline Bins

Inert raw materials like fine & coarse aggregates are stored in bins called as “Inline Bins” where the trucks carrying fine & coarse aggregate can dump the material easily.

The aggregates required are fed by the means of aggregate belt conveyer. On the aggregate belt conveyer, the aggregates are weighed automatically by means of computer form the computer room present on the plant.

Silos

Inert raw materials like fine & coarse aggregates are stored in bins called as “Inline Bins” where the trucks carrying fine & coarse aggregate can dump the material easily.

Cement & Fly ash are stored in airtight container called as “Silos”. The required quantity of cement & fly ash is extracted by the silos. There are two cement silos and one silo of fly ash.

he capacity of cement silo is

2 x 130 tons = 260 tons

Cement and Fly ash are fed to holding hopper with the help of a screw conveyer.

A heavy-duty cement screw conveyor is fixed in inclined position to convey the cement from Manual Feeding Hopper to Cement Hopper. A suitable drive unit is also provided to drive the screw

The screw conveyor body and the screw are manufactured from heavy duty ‘C’ class pipe and the flutes are fabricated from 5mm plate. Running clearances provided between body and flutes for smooth running. The screw is supported on both ends by bearing and at center by hanger bearing having renewable hard bush. These bearing can b adjusted with setting nuts so as to have proper alignment.

The screw conveyor is provided with suitable vertical supports. One inlet connection is provided at the bottom end where manual-feeding hopper is connection & one discharge connection at the top from where the cement is discharged to cement weighing hopper. Flexible joint is provided between discharge connection & cement weighing hopper.

[CE 1.8]

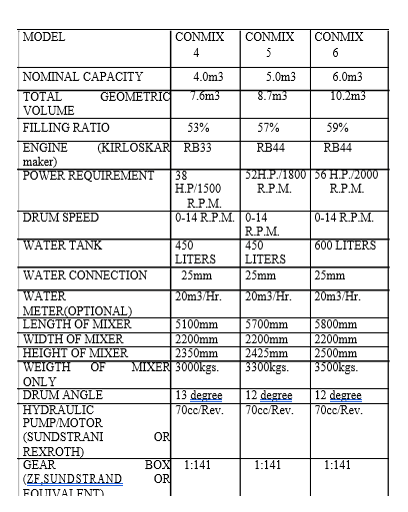

Technical Feature

[CE 1.9]

Mixing Process

Following are types of mixing of concrete.

[CE 1.10]

Tests Carried on R.M.C

All the ingredients used for preparation of the concrete, are thoroughly tested for their quality and physical properties in a well-equipped laboratory attached to the plant for conformity to relevant Indian Standard Codes.

The moisture probe determines the water content in the sand and aggregates. This accordingly helps in fixing the proportion of water to be added for the preparation of the mix.

The sand being used is passed through the mechanized sieving system, before feeding for mixing.

Trial mixes are carried out and tested to ensure that each batch of concrete coming out of the plant meets the parameters of client’s requirements

The sand being used is passed through the mechanized sieving system, before feeding for mixing.

I carried out following tests on Fine Aggregates

I carried out tests on Coarse Aggregate

[CE 1.11]

I drafted the Merits of R.M.C as following

I drafted the Demerits of R.M.C as following

[CE 1.12]

I completed the project successfully and detailed all the aspects of Ready Mix Concrete.

I completed the project report efficiently and within the stipulated time. I did all the management of the project and calculated multiple aspects of the project very well. In case of any issues I always contacted my project supervisor. I also consulted internet resources and library for resolving the calculation issues.

Ready Mix Concrete plant is a modern technique of production of concrete in large quantities away from the actual site of placing. It is very useful in cities where demand of concrete is very high and construction sites are in congested areas where mixing on site is not possible. It is suitable for projects like Dam, Roads, Bridges, commercial complex, Malls and all types of mass construction where time limit plays a vital role and where demand is huge.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)