This report includes the task that I performed in the project entitled as “Design an Open-Wheel 800 CC Car according to Aerodynamic for SUPRA SAEINDIA 2011” during my bachelor in mechanical engineering from Manav Rachna International University, India. I was positioned as a team leader along with other three members to perform this project under the proper guidance of the project manager. The duration of my project was about 7 months i.e. from January 2010 to August 2010.

SUPRA SAEINDIA is the racing exhibition where the formula one cars designed by engineers are demonstrated and the performance and speed of cars are checked by the exhibition team. This project was intended to design and assemble the cars in such a way, which is best suited for the race competition. The project was carried out for the development of the fast speed engine of the car. For the proper weight distribution, the frame was selected with definite measurement. The CO2 canister was provided to generate the propelling force for running the car. I employed the Cosmos software to design the racing car in this project.

I performed this project with my team members to achieve the best car design. Hence, I set out some objectives for the project to be performed.

The objectives are mentioned below:

During the project execution, I performed several duties to complete the project in an efficient way.

The duties are enlisted below -

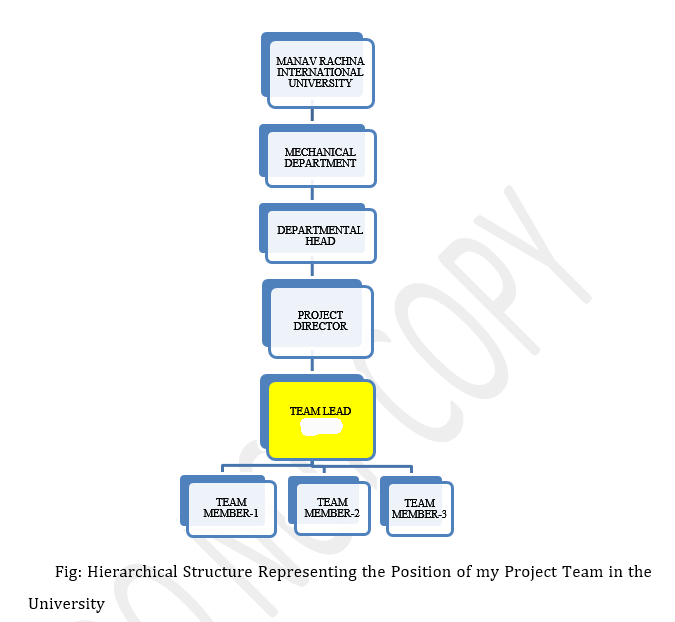

I prepared the chart to represent my position as well as my team members at the University which could be shown as below:

At the starting phase of the project, I consulted with the project manager to get the ideas on the project design. Further, I studied several journals, research papers, and articles published on the modeling as well as designing of F1 racing car. After gathering the information about the design from different sources, I prepared the project plan in the Microsoft project planning software and designed the rough sketch of the racing car and shared it with my project team to get their acceptance. Next, to that, I started to design the components to be used in the racing car. In the design phase, I designed the clutch system, brakes system, gearbox etc. to know their suitable specifications for 800 CC engine.

Also, I designed the car chassis considering the drag force to be acted in the design. In the chassis design, I noted that the dimensions at the front track of the car must be above 75% dimension of the backtrack. After the completion of the design phase, I started the layout design in a 3D model utilizing the Computational Fluid Dynamics knowledge in the SolidWorks software. In this stage, I modeled the car chassis and provided the 2 numbers of the axle with 2 pairs of wheels on it with an open position. Then, I designed the diffuser to minimize the main hoop area and to direct the flow of air towards the radiator inlet for the cooling purpose and decreased the drag force.

Further, I provided the cockpit location at the middle of the car and mounted the engine near the rare wheels which in turn connected to the drive shaft. Then to connect the gearbox to the clutch mechanism, I linked the drive shaft to the gearbox. Also, I positioned the steering with a computer control system for the synchronization of speed with the throttle, steering & clutch mechanism to provide the stability at sharp turns and to assist formula F1 pilot. Moreover, I positioned the pushrod for the front suspension system, a front bulkhead for the driver & car safety, aileron to provide ground force to stick the ground during high speed. Moreover, I designed the racing car positioning each component in the SolidWorks software and ensured its efficient and safe run on the track through Cosmos software.

As soon as the 3D design of the car was completed, I inserted the design model in the ANSYS software and performed the test for different parameters such as air drag, stress on chassis, crash analysis, the performance of components etc. to ensure the working of a racing car. After receiving the positive test result from the ANSYS, I moved for the further procedure. I prepared the bill of materials required for the project such as mild steel tubes for the chassis, CO2 canister, throttle, gear shift lever, gearbox, brake system, clutch system, computer system, hydraulic circuits, aileron, drive shaft and overall items for the project with their quantities and specifications. More, I estimated the approximate cost for the components and shared with my project team.

Next, to that, I collected the hardware items and then started the fabrication and assembly of the car. I bent the mild steel tubes, cut it as required, welded it and made the chassis of the car as a designed model. Thereafter, I positioned the cockpit, driver seat, suspension system, wheels, gear, clutch, brakes mechanism, and the engine properly as per the designed model with the high tension nuts and bolts. Further, I used the 2 hydraulic circuits for controlling the disc brake with separate brake fluid reservoir. After that, I mounted the aerodynamic fiberglass on chassis with bolts and nuts. Then, I connected the aileron at the back side to provide ground force to F1 formula that would stick to the ground during the high speed. After the completion of hardware assembling of the car, I rechecked it along with the project manager and then carried out the testing of the car. After the successful testing, I performed the car painting for the better look of the car. Finally, I prepared the project report including overall project task.

For any automotive vehicle, providing a cooling system for the engine was the most important task in order to cool the engine and protect from engine seizure. Also, the aerodynamic properties of the car must be good. By considering these things, I designed the diffuser for the car underbody in such a way that it minimized the main hoop area, followed the air to radiator inlet for cooling and improved the aerodynamic property of the F1 racing car.

I conducted the weekly meetings with my project manager and the team members, where I shared the progress of the project as well as the project related issues coordinating properly with the teammates. I politely behaved with the suppliers while negotiating for the hardware materials, and also for the timely delivery of the materials, which helped me to complete the project within the project duration. Also, I achieved some technical ideas from the HOD and other professors in the department, and I got proper guidance from them as well. More, I prepared the project report and shared it with my project team, project manager and my department professors. I had proper synchronization with each person involved in the project.

I followed an ISO 45001 for the safety management system during the project execution. Further, I obeyed the rules of my university and the mechanical department and completed the project within the project duration. More, I followed the ISO 26262-1:2011 for the functional safety of road vehicles and ISO 9897 for the chassis design. I followed the overall standards associated with the project. Moreover, I followed the ASMI standard for the overall design.

I performed the design of the car in such a way that provided the better aerodynamic properties. I used 800 CC engine and provided the computer control system for efficient turning even in high speed. The car model was designed by SolidWorks software and analysis of designed model was carried out using ANSYS software tool. I did the hardware assembly of the car and achieved the result as aimed with better efficiency. As I was the project leader, I gained the leadership skills as well as project management skills. As I communicated with my project team daily, I gained the knowledge of communicating properly in the field and also acquired presentation skills. I enhanced the engineering skills and boosted my self-confidence.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)