| Time duration | May 2016 to Jan 2017 |

| Location | Brazil |

| Organization | Ford Motor Company |

| Project | Engine Assembly Line Rebalance |

| Position | Manufacturing Engineer |

[CE 3.1]

This career episode links to project titled “Engine Assembly Line Rebalance’’. This project was carried out during my tenure at Ford Motor Company as a Manufacturing Engineer.

[CE 3.2]

Ford Camaçari plant was presenting the inferior hours per unit indicator as compared to all Engine plants of South America (According to the reported results on The Harbor Report i.e. annual productivity report).

HPU = Total of hours worked by the total of the assembly line employees divided by the Total number of engine manufactured

2015 Camaçari Engine Plant = 8.9 HPU (Volume of 58 540 units)

2015 Benchmarking: Ford Taubate Engine Plant = 4.9 HPU (Volume of 284 000 units)

The volume of production depends entirely on the marketing conditions. It was needed to work reducing the number of employee at the assembly line to make it more competitive. So it was required by the South America Manufacturing director that I work with the Camaçari’s team for defining a plan to improve this indicator because I was the responsible for leading the Harbor Report in the South America region.

[CE 3.3]

The scope of the project was to identify opportunities to reduce the number of employees at the assembly line. The aim was to reduce at least 15% of the total employee currently working at the assembly Line.

[CE 3.4]

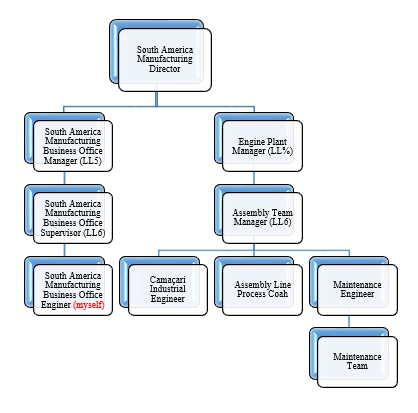

I was responsible for work with the Industrial Engineers from South America plants to reduce the total of Hours per Unit manufactured. The project Hierarchy is given below.

[CE 3.5]

I was responsible for the management of the whole scenario. I drafted all the required documentation of the project & made it possible to have a seamless synchronization amid departments. I also took care of all the project documentation.

[CE 3.6]

[CE 3.7]

The most problematic situation was to identify how to lessen the quantity of employees once the plant was already working with the minimum required manpower for operation with just one shift. The issue was that the plant was designed to produce around 206,000 engines per year in two shifts with maximum efficiency. Due to economic crises in Brazil plant required volume was pretty low: 56 000 for 2015, 86.000 for 2016, just 42% of its capacity, and the forecast for the year 2017 were 70.000 i.e. 34% of the plant capacity.

After numerous meetings with the team and analysis of the line balance, an opportunity was identified by me to eliminate some manual stations by adding their activity to other stations. This will result in the increase of the line speed while attending the new volume required.

All the stations were analysed by the team of the engineers working at the plant under my supervision & discussed their views during meeting. There I defined a line rebalance plan implying MODAPTS methodology to calculate each station cycle line on the GSPAS System.

[CE 3.8]

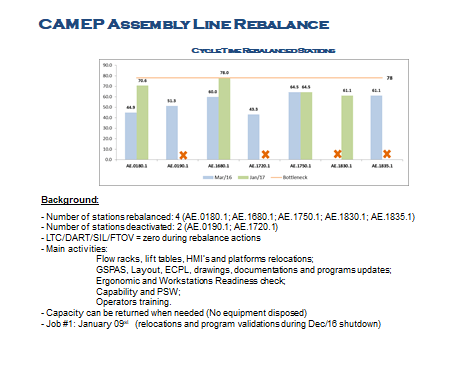

After rebalancing the stations I reached to a final plan of 15 manual stations elimination from the total of 71 analyzed. Additionally, the other operations were rebalanced increasing the cycle time to a maximum of 82 seconds. This was enough to attend the volume being forecasted. Current Cycle time was 66 seconds.

[CE 3.9]

Plant Capacity in 2 shifts (designed when of its implementation):

235 work days per year * 16 working hours per day * 3600 to transform hours in seconds) / 66 seconds per engine = 205 090 engines per year

Plant Capacity in 1 shifts (current):

235 work days per year * 8 working hours per day * 3600 to transform hours in seconds) / 66 seconds per engine = 102 545engines per year

Plant Capacity in 1 shifts (target):

235 work days per year * 8 working hours per day * 3600 to transform hours in seconds) / 82 seconds per engine = 102 545engines per year = 82 536 engines per year

The Line Rebalance consisted of the elimination of 15 stations – Activities were transferred to all the other stations. Stations being either eliminated or automated:

AE 190.1 – Load 4 MBC with liners & zero torque them with spindle fixture

AE 250.1 – Oil Pan Dowells, Knock sensor

AE 360.1A – Oil Bores & Piston stuffing #2 ( become Automated )

AE 370.1A – Piston Stuffing (PRA) bore #1 & 3

AE 480.1 – Install sprocket to crank, pump belt, oil pump assy, oil pump cover and R/D 3 oil pump bolts

AE 580.1 – Place cam cap/cam fixture to the assy pallet. B/O vacuum cap and place it to pallet fixture Z/T 2 head bolts

AE 690.1 – Back out cam cap 16 bolts. Remove intake/exhaust cam caps 6 bolts and place to tray. Remove caps bolts 2 & place to tray ( become Automated )

AE 990.1 – Front Cover Bolts

AE 1080.1 – Install Crank Position Sensor & Damper Pulley

AE 1230.1 – Install Blanking Plate

AE 1360.LH – Install Oil Pan Bolts, studs and rotate pallet

AE 1830.1A – Wiring harness Map Sensor Station 2

AH 490.1 – Cylinder Head unload

AH 270.1 – Install Steam Seals

AH 340.1 - Install Valve Springs

[CE 3.10]

To implement the changes designed it was necessary to schedule a collective vacation during December 2016 so that the stations were enabled to be deactivated and modified.

I defined the execution plan as below:

Responsible – Assembly Process Coach & Camaçari Industrial Engineer:

Define the layout changes required to implement the line rebalance designed during the meetings

Update the station’s documents (QPS, DCP)

Responsible – Maintenance team under the supervision of the Camaçari Industrial Engineer:

Update all the electronic system of control/ programs: OMS, PLC, RBMs

Relocate the Layout of the stations, including racks, platforms and lift table

Relocate the HMI and pressured airdrops

Responsible – Camaçaro Industrial Engineer, Assembly Process Coach & Manufacturing Business Office Engineer (myself)

Train the operators on the new process designed

Measure the new cycle time to guarantee the reach of the cycle time calculated by MOPATS

Responsible – Manufacturing Business Office Engineer (myself)

Prepare the final presentation, align it with the work team involved in the project and present it to the South America Manufacturing Director

[CE 3.11]

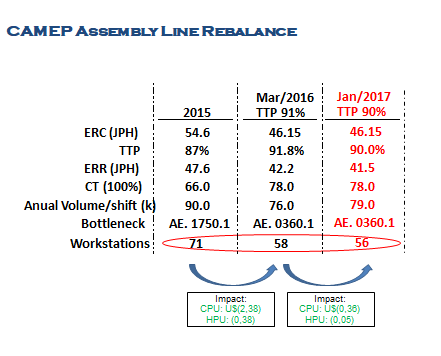

Final Result (January 30th,2017):

Cycle time:

Before – 66 seconds

After – 82 seconds

Assembly Line Operators per shift ( manual stations )

Before – 71

After – 56 ( 21% of reduction – Initial target was 15%)

JPH (100% utilization )= 3600 (seconds per hour) / cycle time

Before – 54.6

After – 43.9

[CE 3.12]

I was able to successfully reduce the number of manpower required to operate the plant at its full efficiency. I worked in congregation with a team of engineers and plant operators in order to execute my plan of rebalancing effectively and effectually. My contribution towards seamless project employment was highly appreciated by the company directors. The project gave upsurge to my professional project management topology and my ability to use all types of resources in resolving issues accordingly. The project as a whole elevated my professional existence in all manners.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)