[CE 1.1]I executed the work duties in the project as a student at Manipal International University:

Title of Project: Copper-Chromium Nanostructures Preparation and Characterization

Duration: [Date] – [Date]

Location: Malaysia

Position: Student

[CE 1.2] Because of the issues deployed with the copper and its alloys, there is an in-depth work carried out in recent years regarding the copper-based nanocomposite materials developments. It has typically gone a decent mile in the elimination of the copper-based materials drawbacks. In recent years, there is a decent effort being made in the copper-based nano-composite development which can be done with the mechanical milling as well as characterization can be analyzed with the usage of the SEM, XRD, and TEM type technologies.

[CE 1.3]The project objective was the copper-chromium nano-composites structure with varied chromium amount. I worked on the powder prepared with the utilization of the scanning electron microscope (SEM) along with the diffraction of X-ray and Energy Dispersive spectroscopy research. I worked on the powder sample compaction which was done with the hydraulic pressure utilization at the required set pressure values. I did the prepared pellets sintering defined well at the controlled atmosphere mainly defined at the provided temperature. Moreover, I characterized the sintered nanocomposites with the utilization of the X-ray diffraction and Scanning Electron Microscope. I implemented the sintered specimen hardness testing with the usage of the micro-hardness and results were analyzed and established with the mixture ration schedule for obtaining the optimum properties.

[CE 1.4]The work proposed was mainly targeting the research related to the characterization and development of the copper-chromium nanostructures which was done with my material engineering understanding in the project.

[CE 1.5]The organogram:

[CE 1.6]The project duties:

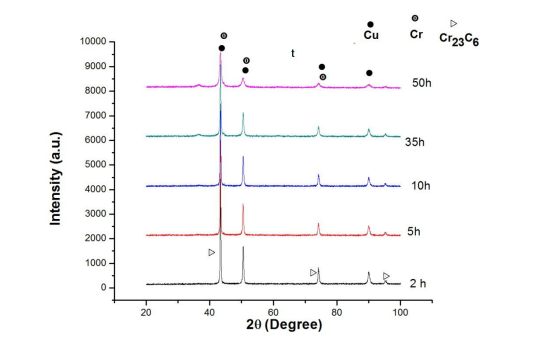

[CE 1.7]I did the milling preparation in the planetary ball mill. I utilized the stainless steel which worked as the milling media and the ball mill mainly rotated at the rpm value of 400 rpm. I used the ball to powder ratio which was 10:1 for milling. I utilized Toluene as the milling media as wet milling which was done accordingly. I collected the powder sample after 2 hours, 5 hours and 10 hours for analysis of milling. I carried out the milled samples X-ray diffraction which worked as the sintered specimens in the diffractometer of X-ray with the PRO high-resolution results. There were various stages for the phase evolution of milling which was done with the usage of copper chromium radiation. I analyzed the data for crystallite size, phases present and lattice micro-strain.

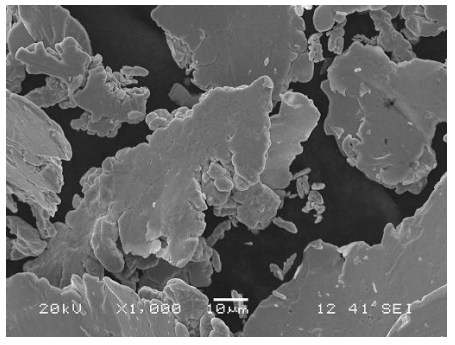

[CE 1.8]I carried out the SEM characterization with the microstructural of the milled powder along with the compacting of the sintered elements. It was carried out with the usage of the scanned electron microscope. I worked on the powder samples micro-structural refinement along with the sintered specimen surface morphology which was investigated for the varied magnifications. I obtained the images from the SEM which provided adequate knowledge regarding the material of nano-composite nature with the variations made in the milling times. I selected the images of SEM for the specimen 1 which was done at the magnification levels of varied nature along with the two locations on each slide. I used 20kV accelerating voltage and EDAX was carried out mainly for checking the nano-composites alterations at various milling times.

[CE 1.9]I worked on identity and phase evolution at mechanical alloying various stages which were done with the XRD analysis utilizing the copper. I obtained the XRD patterns modulation with the compositions of the milling up progress which was up to 50 hours. It was adequate to note that the copper and chromium peaks were clearly visible after milling of 50 hours. I noted that the decrement in the peak intensity decreased adequately and broadened well with the milling progress in both samples. There was the decrement noted in the intensity which was higher in the case of the copper-chromium alloy.

[CE 1.10]I enhanced the milling time which resulted in the crystallite size decrement and further increment in the time resulted in the decrement in the crystallite size. It became constant after some time. I also obtained the rapid increment in the lattice microstrain which assisted well in reaching the constant value and it was due to the mechanical deformation as well as plastic deformation. I conducted metallographic examination of the samples of sintered with the electron microscopy scanning. I performed chemical analysis in the micro-areas which proved to provide higher homogeneity of the carbide phase distribution within the matrix of copper. Even though, I conducted smaller sub-micron particles of the WC phase with the phase main fraction was in nano-metric. I analyzed the TEM examination results which indicated the copper powder sintering parameters in polycrystalline material. I analyzed the homogenous nanostructure which was dominated over the other volume material with the grains growth size of nano-meters. I obtained the microstructure examination results which were based on the input powders. I worked on obtaining the SEM images which were from the electrolytic copper. I worked on the grain size along with the dendrites main axes which were of a 10-20 micrometer order along with the arm’s length and branches mainly ranged from fractions to micrometers. I noted that the carbide powder grains were regular with the fractional size in micrometer.

[CE 1.11]I obtained the images from the SEM which provided the details regarding the microstructural alterations in the material of nano-composite nature with the milling times. I made the specimen 1 SEM images consideration at two different magnification levels with the slide variations made at each magnification point. I utilized the 20kV accelerating voltage. I worked on obtaining the specific decrement in the nanostructure size produced with the increment milling time. I realized that the agglomeration of the powder material was first started when milling process started and after two hours, the structure size was large. The structure size started to decrease in a successive manner with the increment in the milling time. I set the milling time as 2 hours.

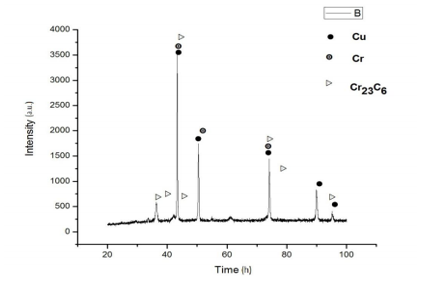

[CE 1.12]I executed the plot which showed numerous phases presence along with the provided intensities in the implemented pellet from the sample under consideration. I obtained the table which showed the lattice strain and crystallite size variation in the pellets which was made from the composition of two materials.

| Parameter | Crystallite Size(nm) | Lattice strain(%) |

| Sample 1 | 122.10 | 0.217 |

| Sample 2 | 96.06 | 0.279 |

It was noted that the crystallite size for specimen sample 1 was smaller than that of sample 2. In the same manner, the lattice strain for specimen 1 was higher than that of the specimen 2. It was because of the higher chromium percentage in specimen 2 as that in specimen 1.

[CE 1.13]I prepared the XRD research of the samples as there was the copper compound phase's introduction along with the chromium because of the milling. It showed that there was a decrement in the size of crystallite along with the lattice micro-strain increment of the implemented nano-structures. I used the lattice micro-strain which enhanced rapidly and slowly with the increment in the milling time. There was an increment in the lattice micro-strain due to the mechanical and plastic deformation. I analyzed the lattice size decrement which occurred rapidly after a certain time and became constant. I made implementation of the SEM which was based on defining the decrement in the formed particle size with the enhancement in the milling time. I attained the increment in the nano-composite homogeneity with the increment in the milling time. I completed the compaction with the usage of the hydraulic press and density was obtained which was in the range of 90-92% after the process of sintering. I attained an adequate increase in the value of hardness from that of the copper with little additions of chromium. Moreover, the nano-composite hardness enhanced with the increment in the chromium amount. My knowledge of materials engineering enhanced significantly with this project completion.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)