[CE 3.1]

I worked on this project as Engineering Manager in National Industrialization Company (TASNEE).

Project Name: HCIS- Integrated Security Systems

Duration: 30th Nov 2014 - 5th May 2018

Project Location: Jubail Industrial City, Jubail, Saudi Arabia

Name of the Organization: National Industrialization Company (TASNEE)

Position: Engineering Manager

Supervisor: Head of Department, Project Execution Organization

[CE 3.2]

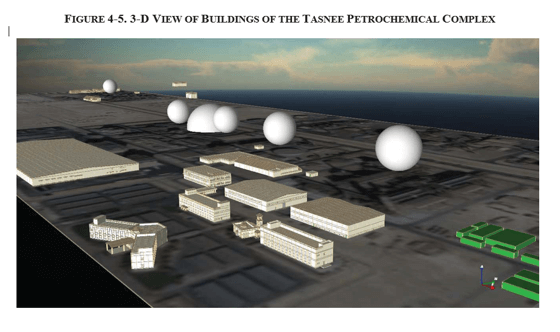

Tasnee was established in 1985 as the first Saudi private sector's fully owned joint stock industrial company with the aim of advancing the economic diversification in Saudi Arabia. TASNEE’s Petrochemical complex in Jubail Industrial City Saudi Arabia's second largest Petrochemical producer, after SABIC. Due to the importance of petroleum, industrial and services facilities, the Saudi Arabia’s leadership urged the establishment of a High Commission for Industrial Security and set the policies and plans to protect such facilities overseeing the areas of security, safety and fire protection, to ensure on-going process of work and production under all circumstances. Thus, a royal decree number 8/439, dated 27/2/1397 H., was issued approving the formation of the High Commission for Industrial Security with H.R.H. Crown Prince, Deputy Premier and Interior Minister as its Chairmen, and membership of a number of heir royal highnesses and their excellences.

[CE 3.3]

The High Commission for Industrial Security (HCIS) had made it mandatory for all Petrochemical Companies to upgrade their Security Systems for compliance to the HCIS Directives. Hence, the project charter was compliance to HCIS 2010 Directives and implement all necessary changes to the TASNEE Security Infrastructure.

[CE 3.4]

My duties and responsibilities in the project were:

[CE 3.5]

The organizational chart below showed my position in the project:

[CE 3.6]

After reviewing the HCIS 2010 Directives, I had prepared a Project Scope and assigned resources. I had put together my team with the following discipline engineers and assigned them the followings tasks:

[CE 3.7]

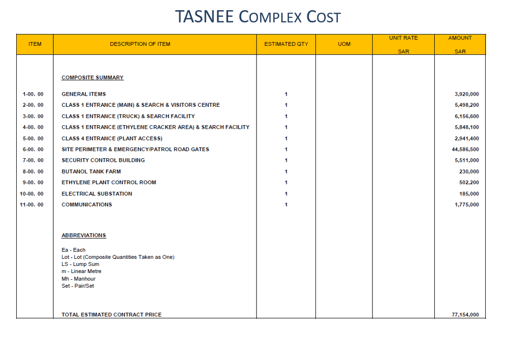

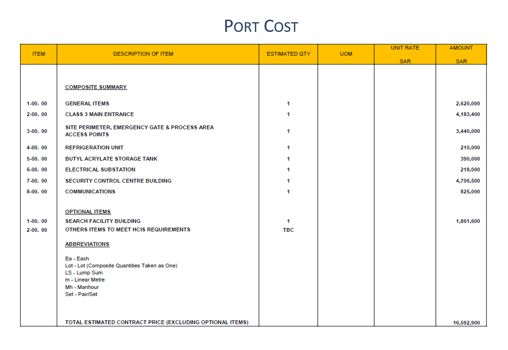

The project started off with the FEED phase and I worked with the HCIS Consulting firm to review the 30% and 60% Models. After completion of FEED, I used the MTO (Material Take Off) and assigned each of the discipline engineer assisted in coming costing data. I prepared Cost Estimate to be presented to the management for budget. Below is the precis of my cost estimate results:

[CE 3.8]

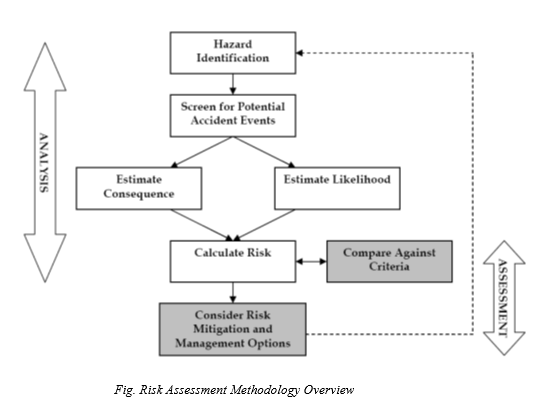

The above costing data was then used to compare actuals vs planned as a tool to manage costs. I used the following stepwise Risk Assessment methodology for the project to develop a risk matrix.

Step 1: Identification of major accident event.

Step 2: Modelling of potential consequences.

Step 3: Calculation of frequency of hazardous event outcomes.

Step 4: Calculation of risk levels.

Step 5: Comparison of risk study results with acceptable risk guidelines.

[CE 3.9]

I identified risks, maintained a risk register and updated risk which helped the project a lot to keep on track and avoid cost overruns and schedule slippages. I did a market survey and prequalified contractors to execute this project. Based on the FEED, I prepared the SOW and RRP package for the construction companies specializing in implementing safety projects. I reviewed the bids received form a technical standpoint and later once the commercial bids were opened, I was assigned to go back to the BOM (Bill of Material) and do value engineering to see where quantities can be optimized. These iterations in value engineering resulting in much lower final bid price.

[CE 3.10]

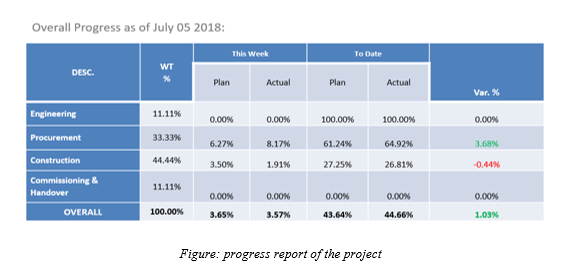

As part of the project progress reporting, I had directed my team to give me periodic input regarding the project progress. I had to conduct high level monthly internal and external customer project progress meeting Internal clients included staff from Operations and external clients included personnel from Industrial Security. One of the mandate from Industrial Security was that during the execution of the project, the perimeter security shall not be compromised at any given time.

[CE 3.11]

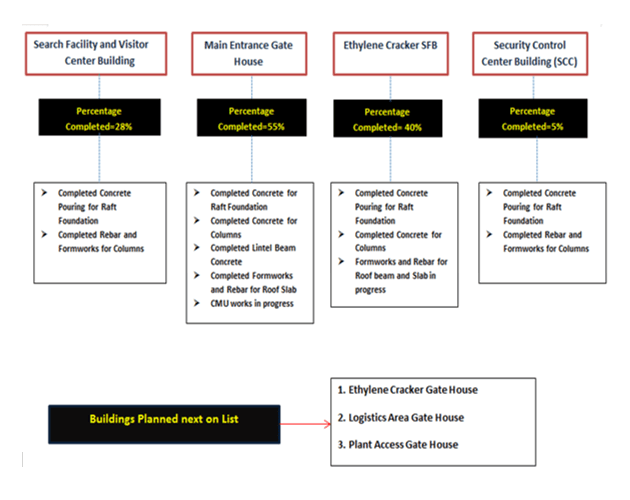

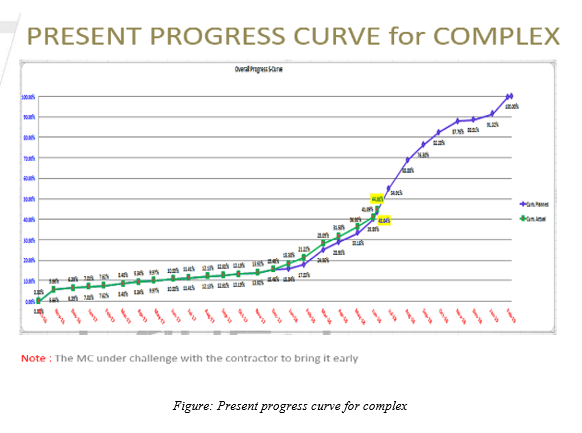

I had to monitor the project progress and keep vigilant about the variations between Actual versus Planned, so mitigation steps can be taken. The project performance was being continuously monitors with inputs coming from various lead engineers. Below is the except from a presentation I made in an internal progress review meeting:

[CE 3.12]

I was involved in managing my team staffs and I had the safety officer to put up safety signs. I had arranged the regular awareness program among all the team staff about the security system. Then I was involved in conducting the morning toolbox and a weekly management safety walk through. After that, I conducted the regular meeting for assigning the safety signs in each block of the buildings. Additionally, I researched various safety tools and arranged them in the procurement order for assigning each safety sign. While selecting the safety tools, the power consuming and cost effective safety tools were given priority. Furthermore, I arranged a meeting with the project coordinator for the arrangement of the best safety tools that suit the designed security system. Finally, I arranged the training of the project coordinators with the high-class family of the safety signs managing team.

[CE 3.13]

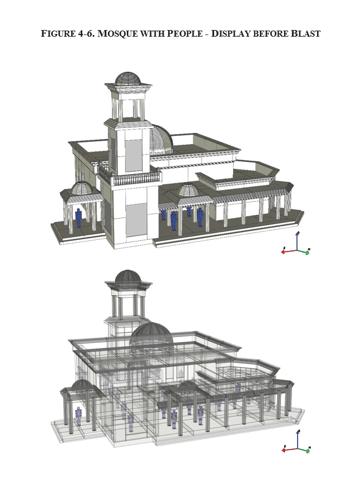

The following were the main difficulties that I faced during the project time -

Based on the blast consequence analysis conducted, I concluded that:

[CE 3.14] The overall project implementation was successful and had a great learning experience for myself and I shared my lessons learned with my team. The project completed successfully with minor cost impact and schedule delay due to change in HCIS directives from 2010 to 2017, complying to which mean cost and schedule impact. These impacts were managed successfully by myself and my team and were within the project budget. I received certificate of appreciation from the Projects Procurement Manager for my help in selection of main contractor and throughout the bidding process, from technical evaluation of bids to doing value engineering and reducing project costs.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)