| Time duration | November 2012 to April 2013 |

| Location | Dubai, United Arab Emirates |

| Organization | Nour Building Systems |

| Project | Concrete Repair Work for Residential Building at Al Barsha |

| Position | Senior Civil Engineer (Planning & Structural) |

[CE 3.1]

Nour Building Systems was established in the year 1986 in Cairo, and established their branch in UAE on 2007, having about 30 years of experience in Building systems Industry, maintenance and specialized in steel fabrication and erection, with the full time working staff of 80 and an operative work force of 120. The Company is spread into various divisions such as construction, maintenance, property services, facilities management, steel fabrication and erection.

[CE 3.2]

Nour Building Systems is an engineering consultancy firm, which provides the complete engineering services to the real state companies and developers. It comprises of a group of well-trained engineers in all engineering disciplines. The company provides the architectural concept, design of the residential, hospitality and public buildings, to meet the client requirements and expectation as well as the local authority regulation and international standards. That’s in addition to the complete structural, mechanical and electrical design and approvals which required prior to the construction.

[CE 3.3]

Damages in the residential building were identified at the ramp slab, retaining walls, some columns at the basement in addition to the water leakage observed at the sum pit, lift pit, where these damages were due to leakage at the retaining walls and raft due to some week points in the water proofing and the construction joint. Leakage caused some cracks and some corrosion in the steel, shrinkage cracks due to restraint walls of the basements slabs specialty at the ramp slab, and the leakage thru the expansion joint and from the drainage system occurred above the raft and below the slab on grade. Therefore, our main objective was to cure all the visual damages at the structural elements, strengthen the structural elements affected and resolve the water leakage source. The drawings showing the test locations and damages observed along with the proposed repair methodology been prepared and obtained the concerned authority approval.

[CE 3.4]

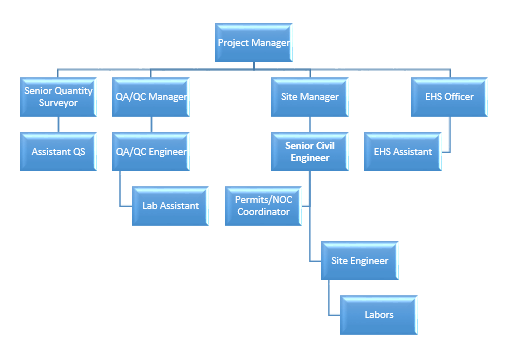

The project Hierarchy is given below -

[CE 3.5]

[CE 3.6]

During the repair work at the 1st basement level and as a part of the work was to remove the slab on grade near the retaining wall for 80cm horizontally and vertically 1.2m of the plaster on the retaining wall. However, during the exposing of the raft and removing the backfilling sand, I noticed that the raft itself is affected by the water table which raised and penetrated thru the construction joint in the retaining or thru any defect part while concrete casting to the raft. I observed that almost 75mm cover was wrapped off and the top steel at some locations was exposed. This diverted our thoughts to conduct certain tests on the raft at certain locations to identify the compressive strength of the concrete, chloride level, steel corrosion status and the humidity level.

Therefore, being the civil engineer in charge in this project, I instructed to develop the exposure part of the raft to 1.0m inside, and to divide the work in to eight parts. I communicated with the lab department to conduct the required tests and provide us the results at the earliest. Based on the results, I requested for a meeting with my line manger to disclose him the situation at site and my proposal to repair the affected parts of the raft. I concluded the meeting to amend our method of statement to include the raft in our repair work at the certain locations required. However, it was required to communicate with the client to inform him about the revised method of statement and additional work required as per the site condition, and therefore the claim for extension of time and cost.

I handled the proper forms and corresponded to claim the additional work and reserve my company’s rights.

Also, another challenge faced in this project was the underground water tank leakage. After exposing the raft around the underground water tank, we observed that the water stopper installed in the tank’s walls were damaged and leakage was coming thru the construction joint and affecting the raft.

I recommended to free up the water tank and take the proper repair and water proofing laying to the inner side of the water tank. The method of statement been revised & included the repair of damaged parts and cracks by polystyrene and crystalline paint and injections, as well as the micro concrete casting for severe damage in the raft. The challenge faced while this part of repair was to provide additional water source to the building added to the roof water tanks. The tank was tested before commencing the work to ensure that no leakage water proofing mechanism is assured.

[CE 3.7]

In this project it was required to design the jacks which should be erected around the damaged columns to carry the load while column repair. With the absence of the design files done for this project, I decided to model the affected columns and apply the actual loads carried, to insure the capacity of the columns is adequate for the demand firstly and secondly to design the jacks.

[CE 3.8]

To determine the physical and mechanical properties of concrete, a comprehensive in situ and laboratory test program was prepared, samples from repetitive structural elements were collected to conduct the following tests:

[CE 3.9]

In this project the safety of the residents and workers was our main intention. Therefore, health and safety procedures been followed strictly to avoid any accident may happen. And for the columns repair, the proper jacks been provided as per the approved design, to ensure that the load path is continued and not distracting.

That’s in addition to the health and safety procedures where I provided a ventilation and vacuum machine was placed at the basement during the grinding work to ensure that dust generated has been suctioned.

[CE 3.10]

After covering all the project aspects and issues, I developed an excel sheet reflecting the daily productivity at site at each zone, manpower, machines, materials, and losses. This daily report, been gathered to combine the weekly report should presented to my line manger to highlight any excess or delay may occur.

During this project I was in daily communication with the project supervisor to check the daily productivity, the work done, and balanced. I was insisting to carry over all the site issues may appear and discuss them with my team to be resolved immediately. In the meantime, work plan and material delivery were discussed on weekly basis to avoid any shortage or delay may appear.

I was leading a team which encompassed site engineer, supervisor, draughtsman and 8 labors, overall 11 personnel. I utilized my personal leadership skills and my knowledge in project management, to drive the project to be successful & free of any gabs or fails.

I prepared Progress daily report, weekly report and cash flow chart were designed for this project. I developed an excel sheet to present the information and figures reflects the site condition and status through the project. The reports were supported with charts and photos reflect the site at all stages.

[CE 3.11]

The project was successfully delivered and completed. The scope of work was achieved and we were successful to get an extension of time and cost to repair the infected parts in the raft.

Learnings from the project are as below -

I learnt the Tests methodology and objectives in this project thru the lab engineer, to originally decide which test to be conducted at what location was really a valuable knowledge. That’s in addition to the knowledge taken from using different chemical repair materials and the fiber carbon technology for the shear and compression strengthen were an updated techniques and technology gained.

To read more.............. Kindly check the below links.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)