[CE 1.1]

This career episode describes my engineering activity during my employment at Al-Toukhi Company for Industry, Trading, and Contracting. In this project, I was working as a Procurement Engineer. I worked on construction of New Muhayil West Substation 380/132/13.8 KV.

[CE 1.2]

| CHRONOLOGY | |

| Project Title | Construction of New Muhayil West Substation 380/132/13.8 KV |

| Dates for the Project | 1st June 2012 to 30th November 2013 |

| Duration | 1 year and 5 months |

| Name of the Organization | Al-Toukhi Company for Industry, Trading, and Contracting |

| Location | Asir, South West of Saudi Arabia |

| My Role | Procurement Engineer ( Electrical Engineer) |

[CE 1.3]

Al-Toukhi Company for Industry, Trading and Contracting are well known as Engineering, Procurement and Construction Company which is located in Riyadh, Saudi Arabia. The company has been giving its services for last 40 years, working on more than 80 electro-mechanical projects on turnkey basis. This company is the main EPC Contractor for Saudi Electricity Company (SEC) and Saudi Aramco. It is particularly famous for building power stations, gas turbine and diesel sub-stations, overhead and underground transmission lines, distribution and transmission substation networks, and turbine inlet air cooling projects. The company has more than 1,500 employees with an annual turnover of 1.5 billion SAR.

[CE 1.4]

The main objective of this project was to meet the growing demand on electricity in Saudi Arabia at that period of time and to be part of the electricity supply grid in the southern area of Saudi Arabia. The project was started to transmit the electricity by constructing a substation, in the southern part of Saudi Arabia. The substation was connected to Shuqaiq and Namera North Transmission Network. It aimed to step down the transmission voltage to sub-transmission voltage 380/132/13.8 KV.

[CE 1.5]

The responsibilities which I carried out as a Procurement Engineer during this project included:

[CE 1.6]

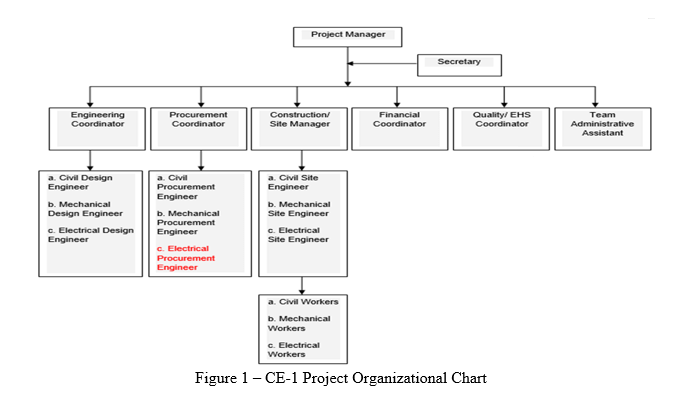

Figure 1 below gives the complete hierarchy of the project, showing my role in red :

[CE 1.7]

In this project the low voltage cables were required and their specification needed to be CU/XLPE/PVC 1KV cables of 9000 meters of 4x16 mm2. The cost of those cables was around 250,000 SAR (60,000 USD approx). That amount was making a high cost of the overall budget. To resolve this issue, I talked with the engineers and we proposed a solution to reduce the cable cross section from 16 mm2 to 10 mm2 making sure that the new cross-section still complies with the project technical specifications. The reduction saved around 100,000 SAR, and that amount didn't disturb the overall budget of the project.

[CE 1.8]

The medium voltage switchgear that was used in the project required to supply of switchgear in a building. When it was going to be executed, an issue popped up in the space of switchgear allocated in the building because the dimensions of switchgear were underestimated in the design. To overcome this, I talked to a vendor and got an offer where the switchgear was supplied in a smaller container. The solution was proposed to the customer and they accepted it. Then, the switchgear was supplied in a smaller container in the allocated space of the building.

[CE 1.9]

In this project I had to design LV cables and Fire alarm system. To design the LV cables and Fire alarm system, I was consulting with a designer.

[CE 1.10]

During this project, also, I was involved in the project cable cross section calculations.

[CE 1.11]

Following training sessions I took during the period.

| Training/Workshop/Conferences/Courses | Dates | Duration | Venue |

| Kickoff meeting with the customer | June 2012 | NA | Jeddah, Saudi Arabia |

| Progress meetings with project team | NA | Weekly basis | NA. |

| Update meetings with customer and top management | NA | Monthly basis | NA |

[CE 1.12]

In this project, I used a few standards of IEC, ANSI, and IEEE during my project.

[CE 1.13]

During the project, I took help from my project guide. I asked about the basic design principles for Low Voltage (LV) equipment and cost-efficient procurement strategies. For many issues and workflows of the project, I negotiated with the vendors/ suppliers. I was working under the supervision of project procurement coordinator, and he was reporting to the project manager. So, I had interaction with my supervisor almost every day to discuss the progress of the project. I was also communicating with procurement management, project management, engineering, and finance responsible team.

[CE 1.14]

During this project, I applied my knowledge of engineering to optimize the design of the substation so I could have saved a cost of a value in the project.

[CE 1.15]

During this project, I used an ERP system for material tracking of the project. From material request to material delivery, all information about the project was recorded through such ERP system.

[CE 1.16]

While working on this project, I had weekly meetings with the project team to discuss the project’s progress. With the customer, I had monthly meetings to let them be aware of the updates related to the project’s work. I had to meet with management once in a month to share the status of the project. My meetings with suppliers were scheduled according to the work of technical and commercial clarifications. I had daily contact with my functional manager, weekly meetings with the project manager, and monthly meet-ups with customer and management.

[CE 1.17]

While working on this project, I was responsible for the handling of electrical material during the project. I had to handle the material from the request phase of the material to the delivery phase of the material. I used a few of techniques to carry out the project effectively. I used to define the problem, analyze the cause of that problem, and then suggest some valuable ideas and appropriate solutions. Among all suggested solutions, I selected the best solution and implemented the corrective action in order to kick out the encountered problem.

[CE 1.18]

In this project, I didn’t have any members who were working under my supervision, as I had to report directly to my functional manager. However, I was leading the vendors/ suppliers to assure a successful implementation of the supply and contract management terms.

[CE 1.19]

During the project, I needed to prepare a report for Material Tracking which was presented to the manager on the weekly and monthly basis. The topic of the report was the purchasing roadmap of electrical material for the project. I also had to make my own follow-up sheet for my record.

[CE 1.20]

While working on this project, I gained a valuable knowledge and experience. I got basic design principles for LV equipment which was used in substations. I learned new time management techniques. I was able to think analytically and solve the problem. I learned to communicate with other team members. I got some advanced negotiation skills.

[CE 1.21]

From the beginning of the project, the environmental health and safety measures were strictly advised by the customer to follow. That’s why we hired an EHS coordinator throughout the project in order to meet the customer’s requirement. This project was a construction site project, that’s why it required some precautions. I had to take measures for hazardous energy control. I took an electrical safety orientation which is necessary for dealing with electrical work. I used to wear helmet, goggles, gloves and working suit, and I also advised workers to do the same. As the project involves working from a height, I took precautions for this to avoid an accident. Driving and vehicle safety were also kept to have a sound and safe working environment.

[CE 1.22]

In this project, I introduced some new strategies that were effective for material cost saving, especially Bundling, Design to Cost, and 2nd Source Development.

[CE 1.23]

While working on this project, I also participated in different social activities. I arranged a public day for school going students to make them aware of the importance of saving in electricity consumption.

[CE 1.24]

By the end of the project, I was able to achieve all the goals and the objectives of the project. The project was a complete success. The substation was put on the operation as per the project time schedule with no delays.

[CE 1.25]

It was an outstanding experience to do this project. I used my various skills and knowledge of engineering degree to complete the project’s activities. I successfully managed to secure the purchasing and delivery of all electrical materials that were required for the project. I was able to complete the project under the allocated budget. The customer was happy with the outcome of the project. Overall, it was a great project, full of challenges and technical gains.

To read more.............. Kindly check the below links.

We hold the apex position in providing services regarding CDR writing for engineers Australia. We are known to have very high success records for consistent team of professional writers having years of experience in the field of CDR preparation. We provide the best and trusted service for CDR writing and reviewing of all kinds of engineering disciplines. We provide services for career episode writing, plagiarism check and removal etc.

Should you need any further information, please do not hesitate to contact us.

Contact: +61-4-8885-8110

WhatsApp: +61-4-8885-8110

(Australia, USA, UK, UAE, Singapore, New Zealand)